Wet sanding for even smoother surfaces.

“Wet” sanding to obtain even smoother and more finished surfaces means using water or cutting fluids during processing. For some manufacturing sectors it is essential.

Working "wet" involves the use of abrasive belts together with a liquid, both to reduce heat and to reduce friction and improve the finish, which for some sectors must be of high quality and with a strong aesthetic impact. It is clear that not all sanders are suitable for carrying out this type of work because working "wet" requires construction aspects linked to the use of stainless steel, a highly corrosion-resistant material.

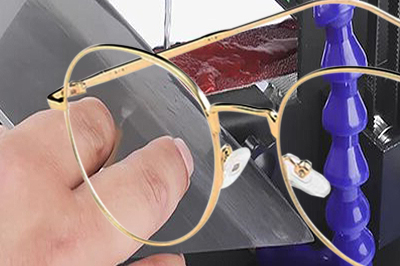

MARPOL FR has designed and produced a sander built in AISI 304 stainless steel, rubber and aluminum to ensure a long life of the equipment.

The project was created specifically for use in the eyewear sector, but we believe it could also be interesting for other manufacturing sectors, such as the glass, stone or mineral processing sectors, in the aerospace sector, to remove small imperfections and obtain smoother and more precise surfaces, in craftsmanship, for the creation of artistic objects.

If you are interested in the 310-INOX sander model, write to cati.gabriele@marpolfr.com to get reseller references.