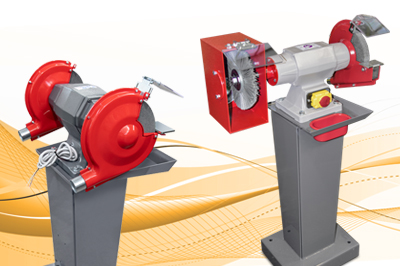

Grinding machines for material removal and finishing

With the use of rotating wheels the material removal process can be precision, roughing, rectification, cleaning.

Precision grinding is a manual operation that involves removing material or burrs from cast parts, bevelling, finishing welded or machined parts, and sharpening. As the processing is manual, it is difficult to determine the amount of material removed. The experience of the operator is decisive, as is the reliability and safety of the equipment used.

Roughing is usually followed by finishing, or rectification, which involves greater care and attention to the quality of the machined surface. Cleaning, sanding and polishing are the objectives of grinding that improve the surface itself without changing it, as is the case with roughing.

This is the reason why grinders are often supplied in combined mode: grinder and brush in the same machine. The type of grinding wheel and grit used, as well as the type of brush, are crucial to the final result of the work. But equally important are the characteristics of the grinder, its ergonomics or working comfort, the way it is equipped with optional extras. The machine must be stable, reduce vibrations to a minimum, be adequately equipped with guards and have an extraction system for dust and processing residues.

If you are looking for a polishing/grinding machine, we are sure that in this section ( entra ››) you will find the model that best suits your professional needs.

Write to info@marpolfr.com

for the contact details of retailers.